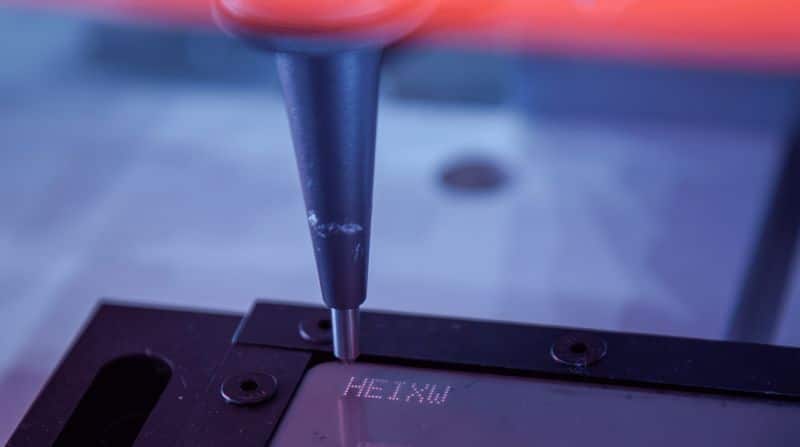

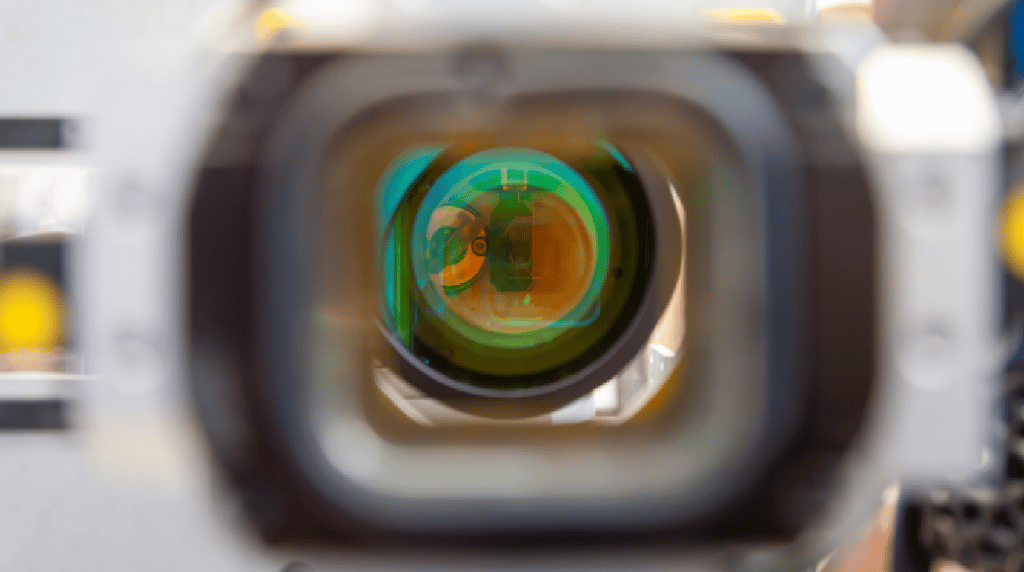

For more than 30 years, SIC Marking has been designing a technically superior range of laser, dot-peen and scribe marking machines.

They trust us

With 30 years’ experience, we are experts in a number of marking technologies: Dot Peen marking, Laser marking and Scribe marking.

Our solutions are robust, technically advanced and tailored to our customers’ challenging industrial environments.

We are present in more than 50 countries, through our network of subsidiaries and exclusive distributors.

We are able to guarantee an optimum quality of service locally, for our customers, and the possibility of managing projects on an international scale.

Our dedicated teams and processes develop the best technical solutions for your specifications.

Consult us!

We are there for you from the deployment of our marking and traceability solutions, in your workshops and on your industrial sites.

Train and support your teams on the introduction and operation of our marking solutions and traceability process.

Send us your parts!

We will conduct the necessary tests and feasibility studies to help you choose the best marking solution.

Customer’s opinion

Industrial traceability implemented on the SKF site. Our customer talks about it.

Contact us

Need information?

Contact one of our experts!