Quality and safety mobilise the industrial world on a daily basis.

At a time of globalisation, product traceability is a core issue for production sites, and similarly for communication between manufacturers and their suppliers or customers.

This system of product tracking throughout the life cycle, from provisioning to end-of-life, including manufacture, sale or utilisation, enables data to be collected and analysed that can then be used for quality management, the identification and resolution of problems or the prevention of recalls.

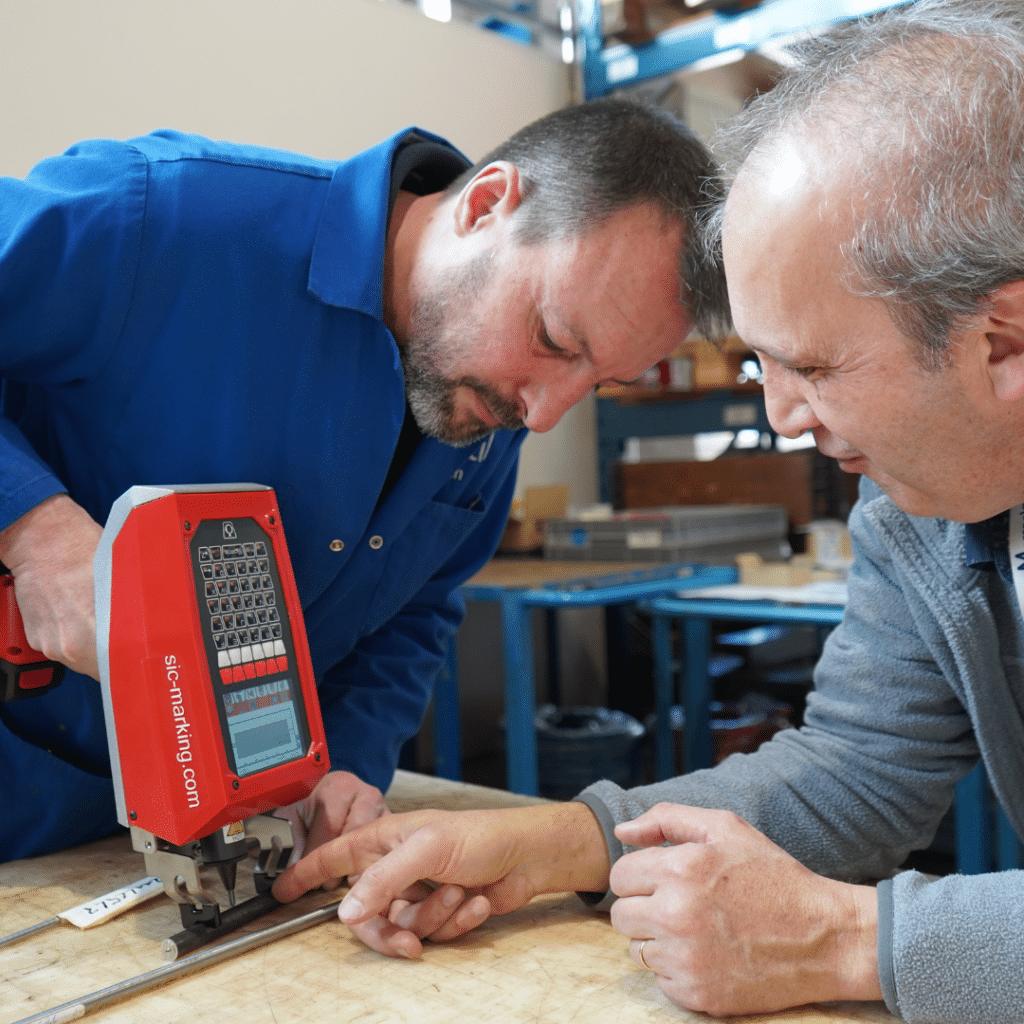

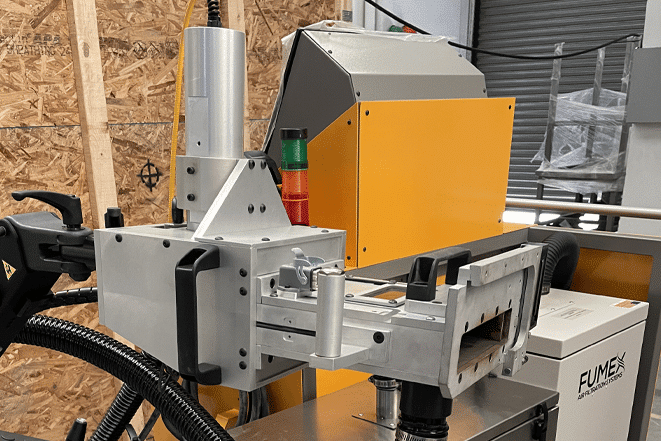

SIC MARKING guarantees the complete traceability of your production by combining a marking machine with one or more reading and identification systems. Do not hesitate to ask our experts to advise you on the choice of marking and viewing solutions best suited to your processes.

Traceability can have two aspects.

The first is “external” and allows product movements to be tracked through successive processes upstream or downstream of a production site, at various manufacturers.

The second is “internal” and allows the path of parts or products to be tracked within a factory or a company, in a specific assembly or manufacturing space.

D

In both cases, the principle involves identifying components or products by marking, and then storing and managing the related information.

Our SIC MARKING traceability system is designed to manage the marking and all the data contained in the markings.

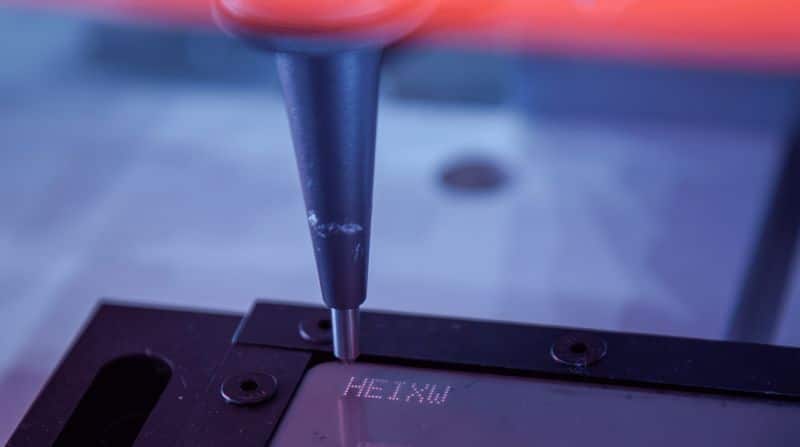

The traceability implementation principle is as follows: the part or product is marked and the system first checks that the marking process has worked properly.

The marking is then analysed by a reading system, in order to confirm its legibility and compliance with standards that have been preconfigured as a function of specific criteria.

The information collected by reading the marking can then be stored in a database (in a PC or directly in the PLC).

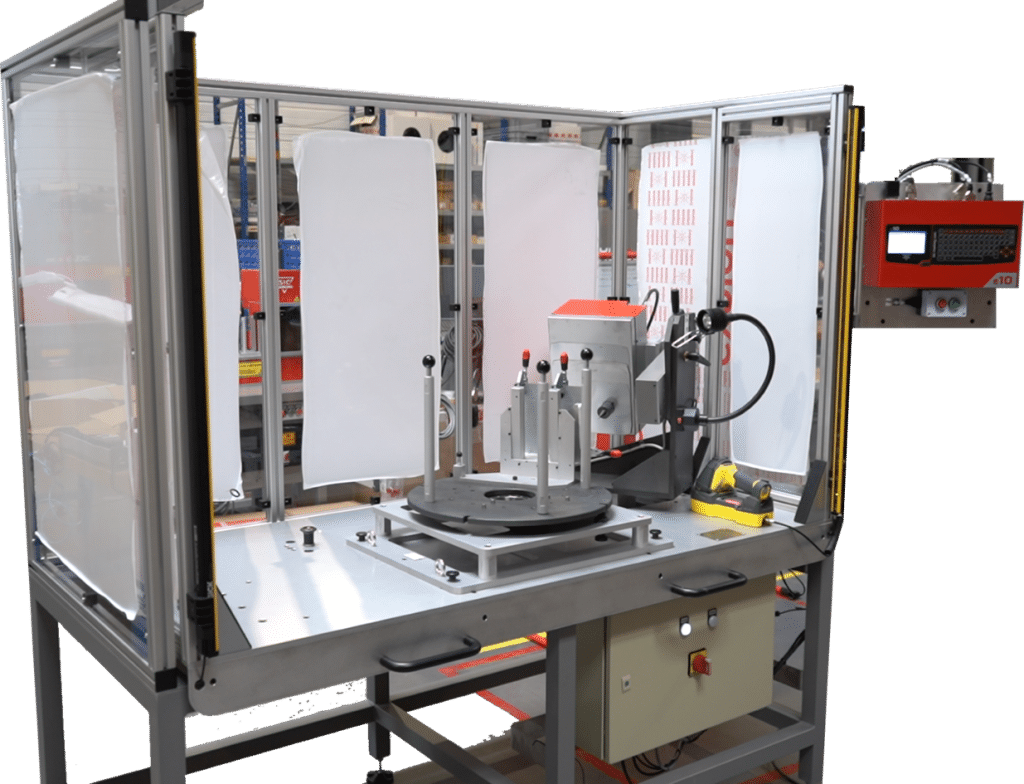

Marking and reading can be incorporated in your production lines and also in standalone marking stations in specific areas (warehouses, measuring and quality control stations, logistics areas, etc.).

Customer’s opinion

Factory 4.0, quality issues, durability of markings, cycle time, etc.

How to meet these challenges?

Our customer SAFRAN testifies!

Our reading solutions are suitable for all types of permanent marking technologies (dot peen marking, laser or scribing) and for all types of marking: 1D bar codes, 2D codes (Data Matrix or QR codes) or alphanumeric characters.

We have a range of fixed cameras and a range of barcode scanners for reading.

We can directly install a reading camera on a laser marking or dot peen marking system, for simultaneous marking and reading on the same workstation

The Data Matrix is a 2D symbol commonly used in industry world-wide. It provides a very high data density and is particularly robust.

It is decoded using an integral camera combined with decoding software.

Complementing our traceability process, our new laser solutions control software, SFA, helps you to achieve immediate gains in productivity by simplifying, securing and automating your markings.

This software controls the source and manages accessories (sensors, axes…) and the use of your marking data.

Vehicle Identification Number, VIN: 3 letters for an acronym that occupies a major place in automotive traceability.

This identification number (marked on the chassis and shown in the log book) ensures the traceability of a vehicle during the manufacturing process and also after it has left the factory.

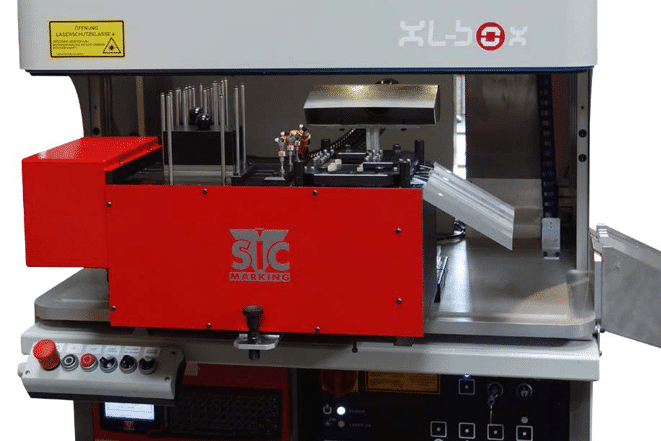

With 30 years’ experience, we are experts in a number of marking technologies: Dot Peen marking, Laser marking and Scribe marking.

Our solutions are robust, technically advanced and tailored to our customers’ challenging industrial environments.

Need information?

Contact one of our experts!