We have many references in the implementation of traceability systems in metallurgy sectors such as forging, forming, stamping, cutting or machining… Depending on the material concerned, the expected rendering, your production conditions and traceability requirements, one of our laser engraving, dot peen marking or scribing solutions will be more appropriate.

Our experts are here to advise you according to your needs, do not hesitate to contact us!

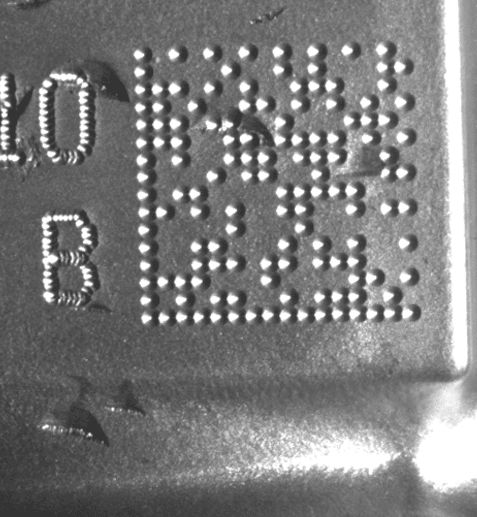

All types of permanent marking are possible on the metal: product identification, serial number, logo, text, 2D code (datamatrix or QR), barcode, etc.

The type of metal to be engraved will be decisive in the choice of the best marking technology: steels, stainless steels, aluminium, titanium, carbides, brass, copper and their various alloys and treatments…

Discover some practical applications below

They trust us

Activity sectors > Metallurgy & Mechanics

Our practical applications

Reading of automotive part markings

The client is an automotive supplier specialising in milling large runs of medium-sized parts.

They supply their customer with machined parts and complete sub-assemblies, such as gearboxes.

The majority of these parts require

marking and reading of a Data Matrix code.

High temperature engine parts

SIC MARKING is involved in the identification of engine components for a large French automotive manufacturer.

What is distinctive about the parts is that they are very hot at the time of marking (aluminium casting at around 300°).

The crankcases processed, with a raw as-cast surface, are shot-blasted and have a grainy surface finish.

Aluminium alloy part

Our client is a Swiss company specialising in casting.

It makes die casting machines for producing aluminium parts.

The managers of the casting company contacted SIC MARKING, as they wanted to be able to provide a marking solution in their casting cells, to identify parts and guarantee their traceability.

Our product lines

Discover other sectors

Throughout our 30 years of development, we have built up our expertise in the automotive, energy, mechanical engineering, vehicle and transport industries.

Discover below our

many examples of laser, dot peen or scribe marking applications in each of these sectors.

Contact us

Need information?

Contact one of our experts!