case study

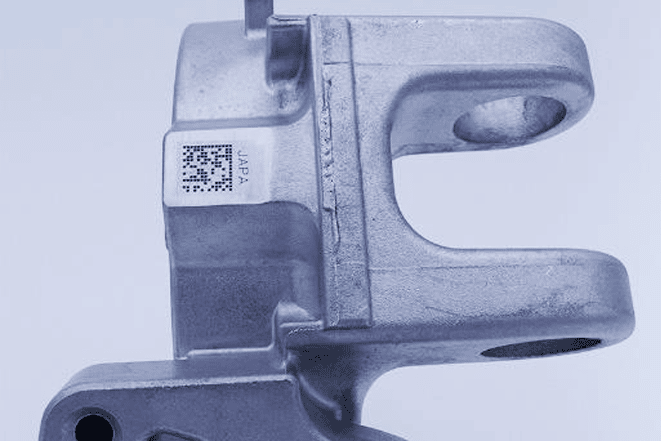

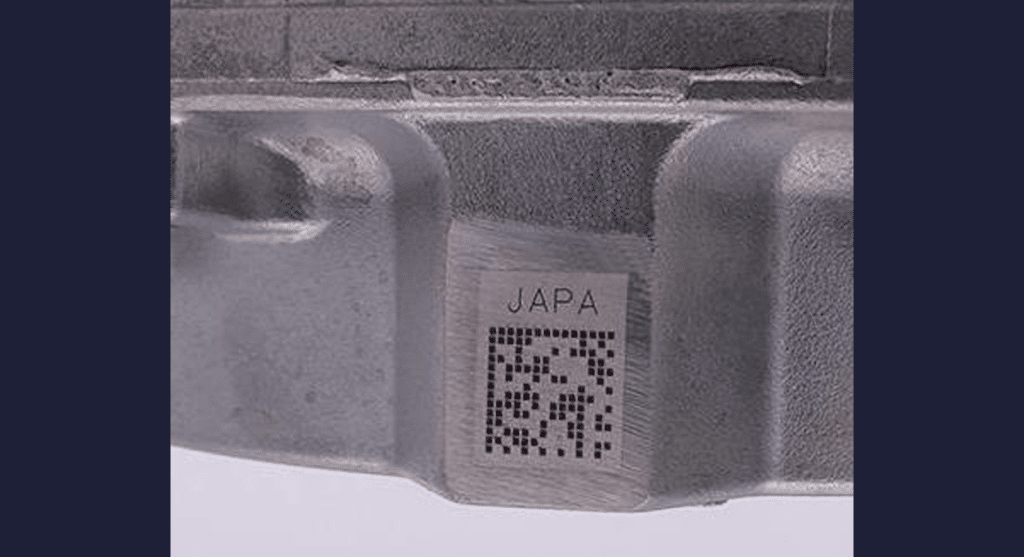

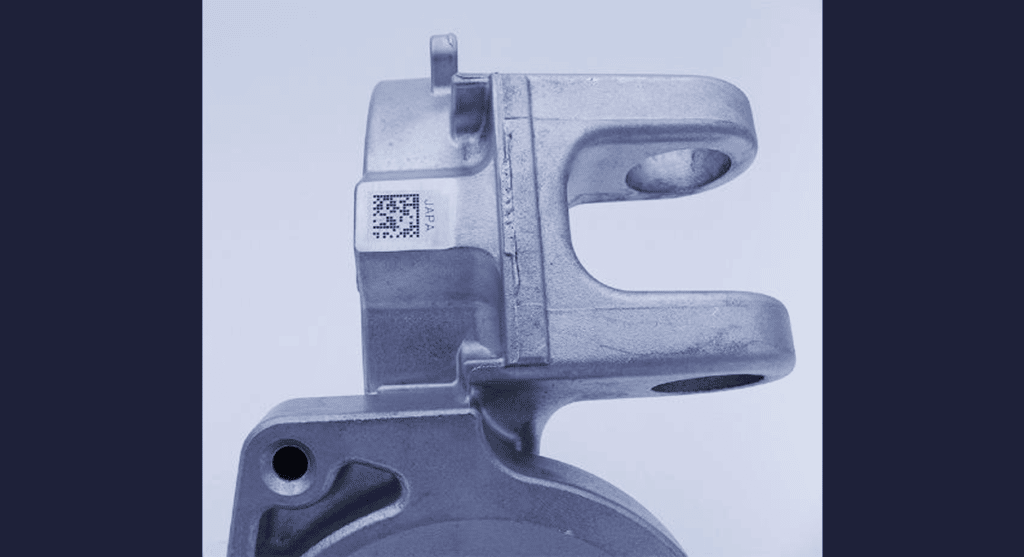

Data Matrix marking on cast parts of variable sizes

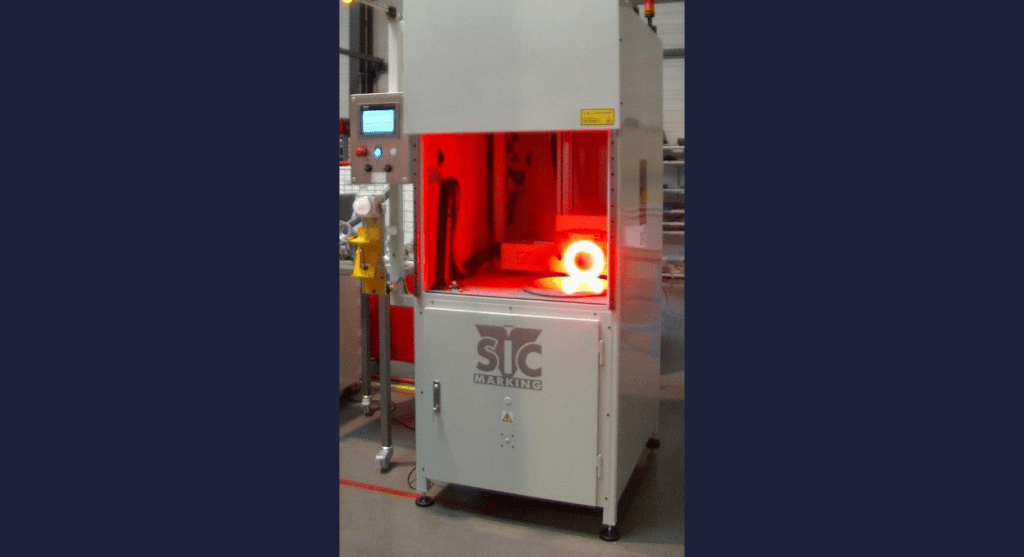

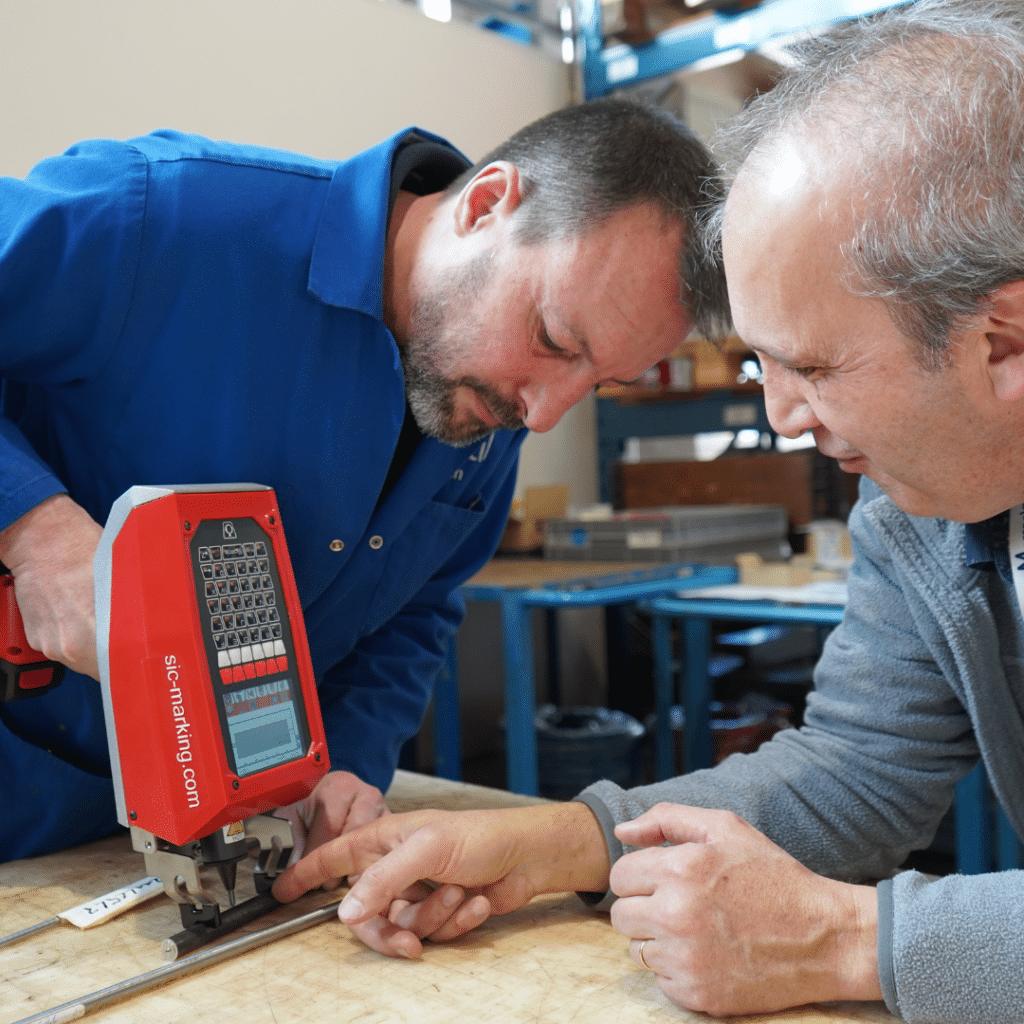

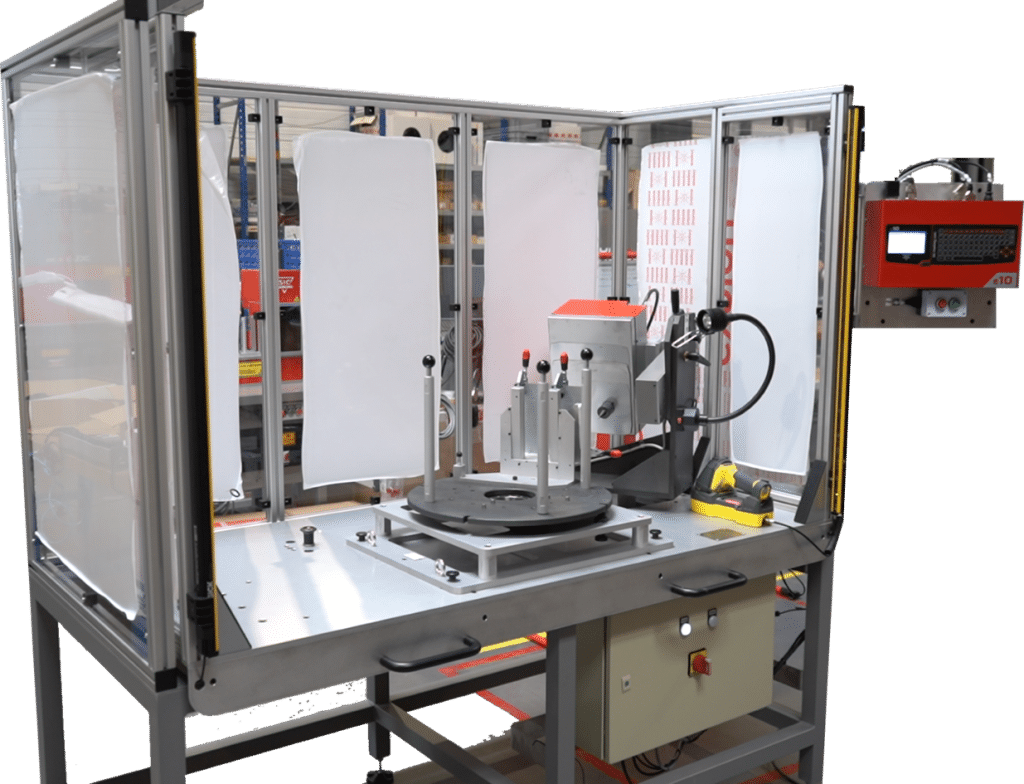

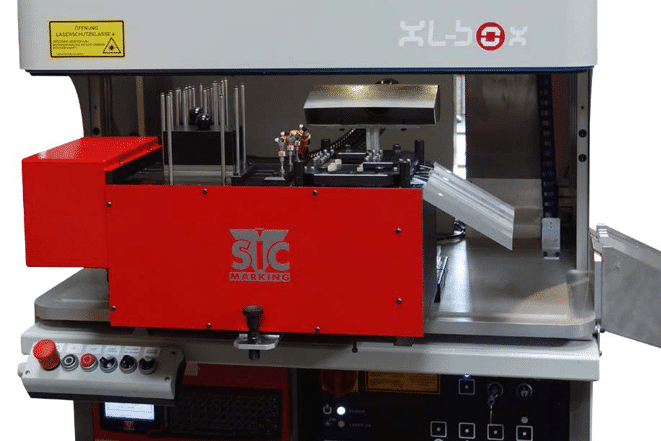

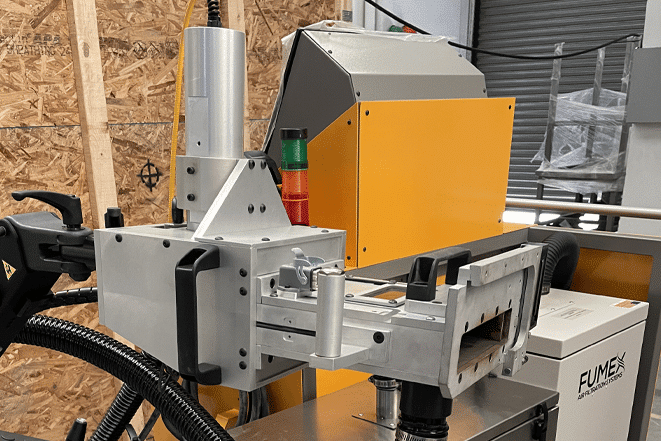

A manufacturer of cast aluminium parts contacted us with a specific request for marking parts of different sizes, after a milling operation.

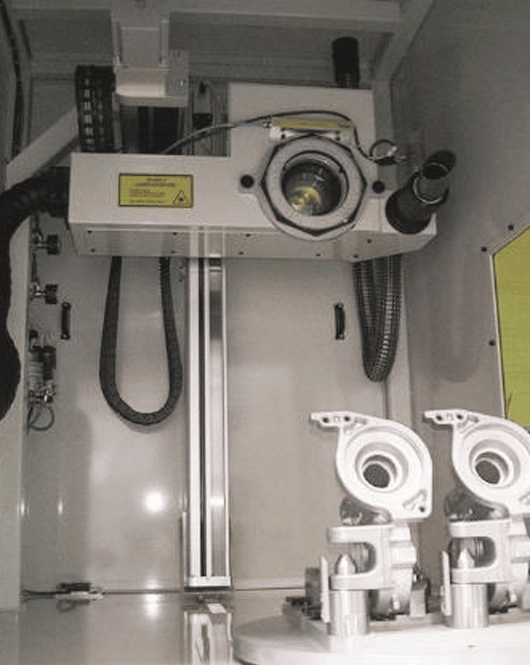

The company has constraints relating to integration into its production line (lack of space, a humid and dusty environment) and requirements in terms of the quality of marking.