case study

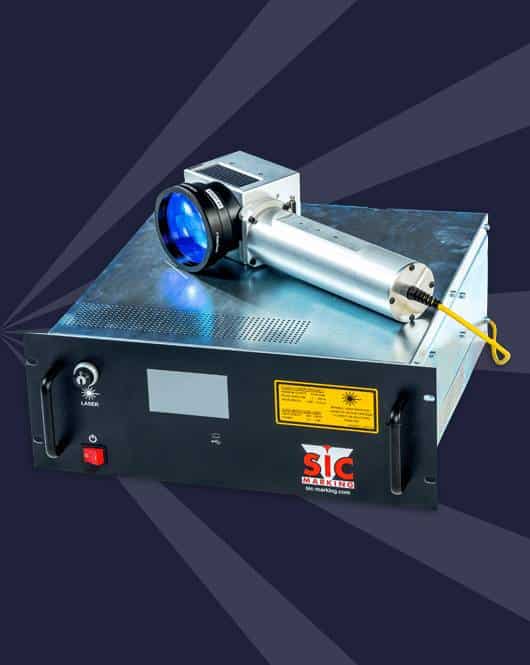

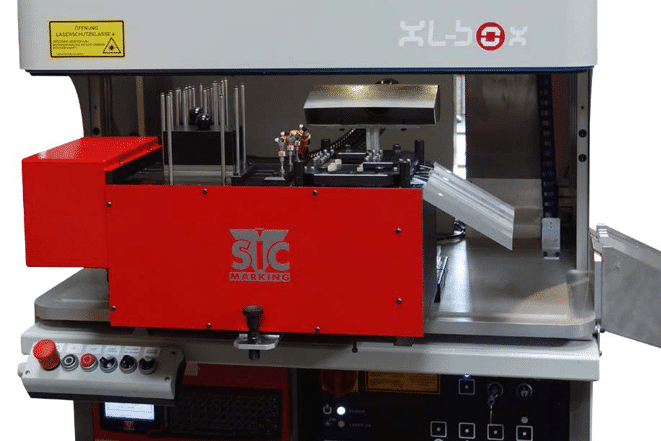

Marking pacemakers using laser annealing technology

The client is a medical device manufacturer looking to integrate a marking system into its high-speed production line, while producing a mark that does not damage the product’s corrosion protection.

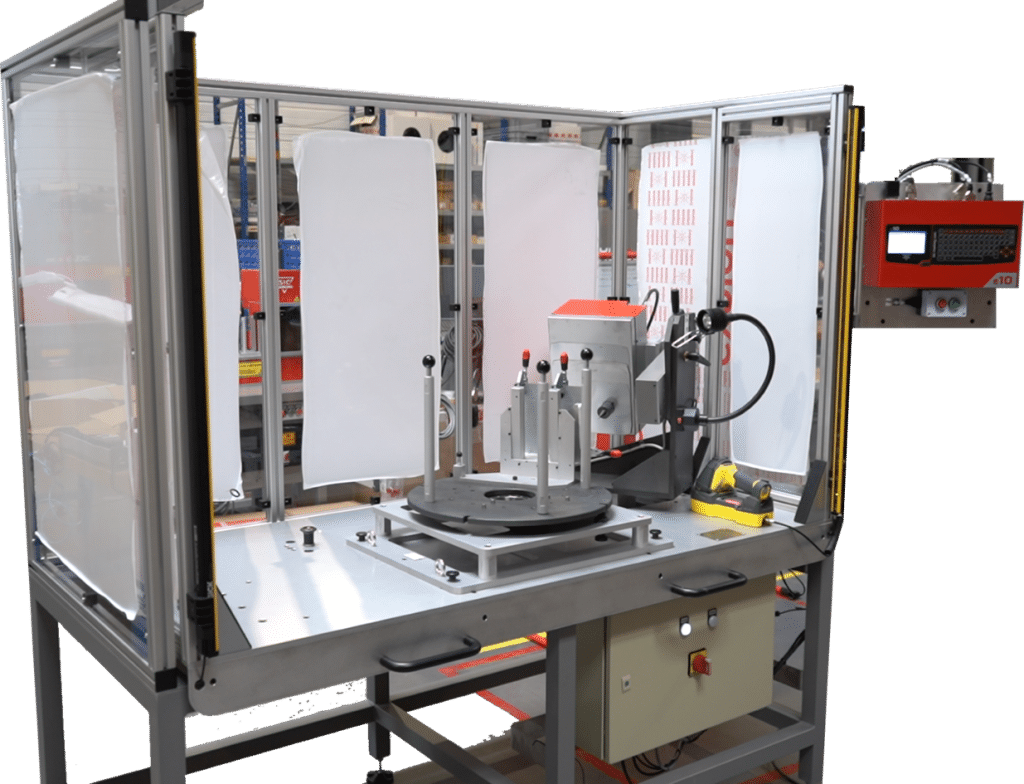

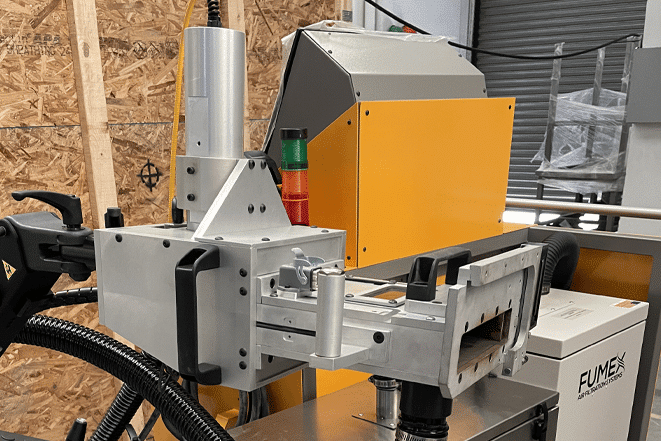

Operation of the machine:

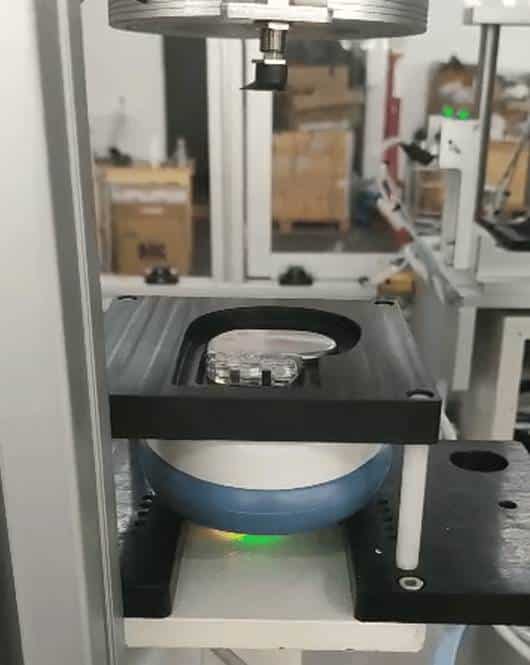

- The cobot automatically loads and unloads the parts to perform laser marking.

A sensor detects the presence of a part, the laser marks it, then a camera reads the Data Matrix code and the alphanumeric characters.