The SIC MARKING

solution

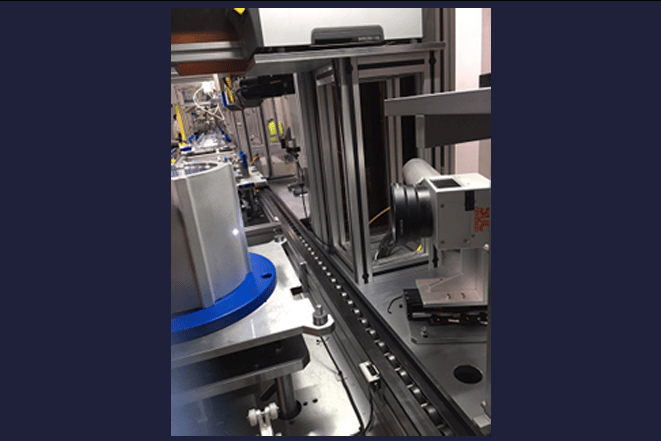

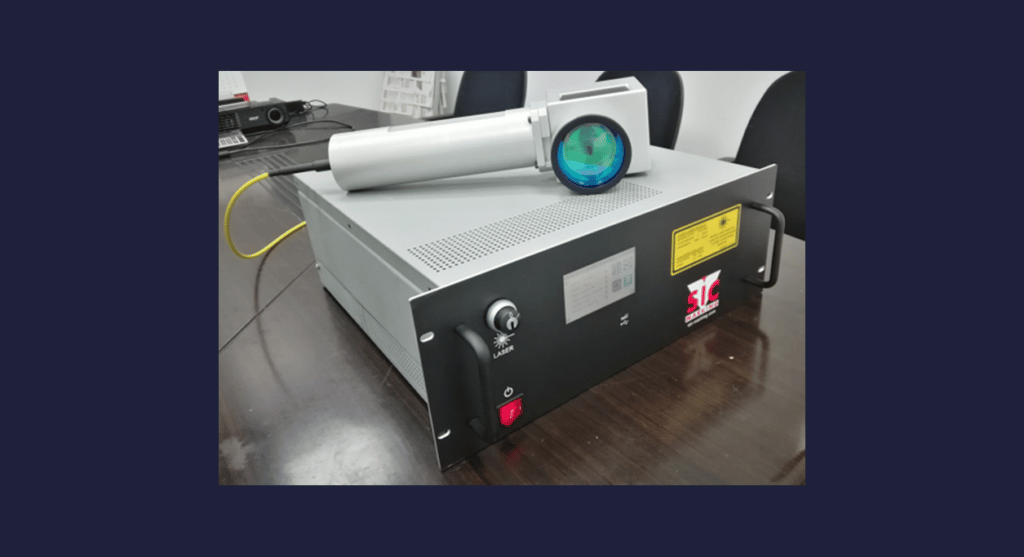

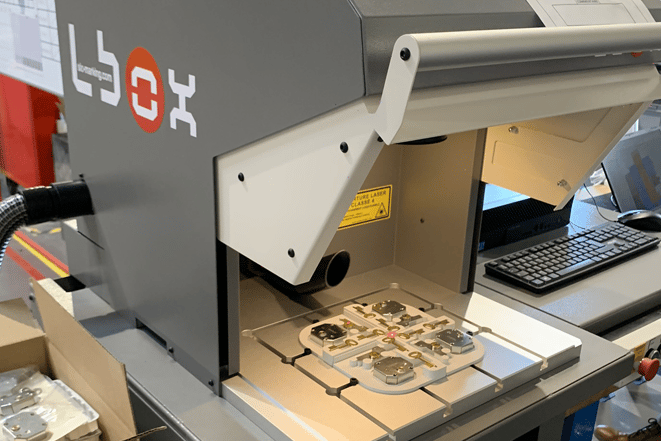

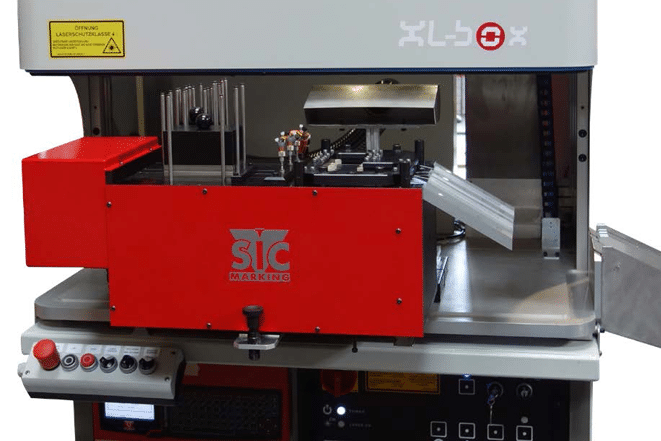

SIC MARKING provided a laser stripping workstation comprising:

- 2 x 100W lasers for stripping the large 8mm wide sides.

- 2 x 50W lasers for stripping the small 2mm wide sides.

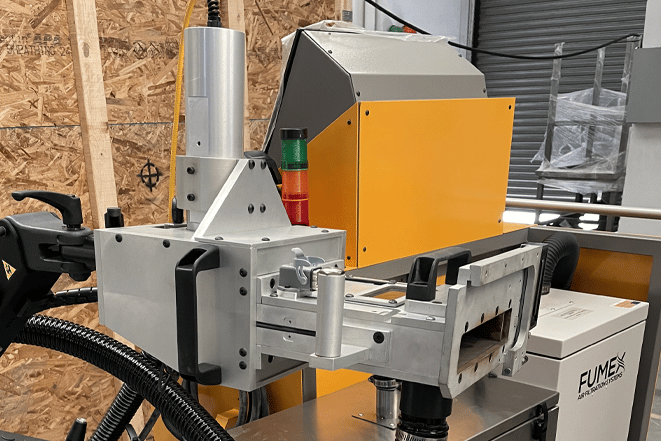

- A conveyor and positioning system for the copper wire.

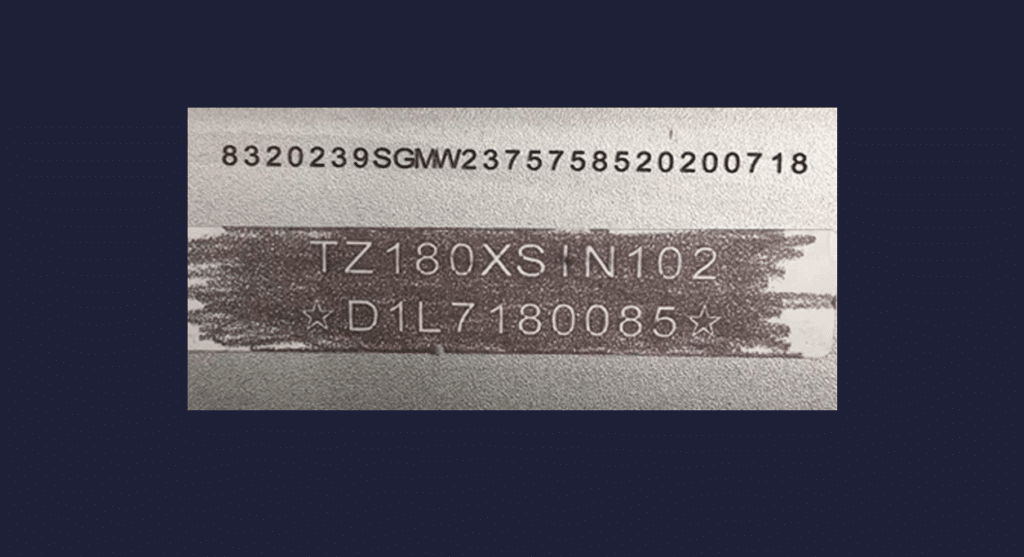

- A system for reading the 2D code.

-

After the winder has unrolled the copper wire over a certain distance, it stops in position, the laser strips all the sides and marks the 2D code.

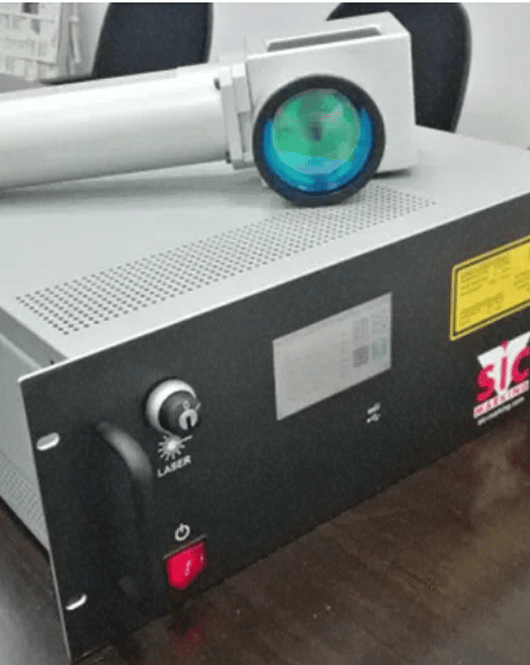

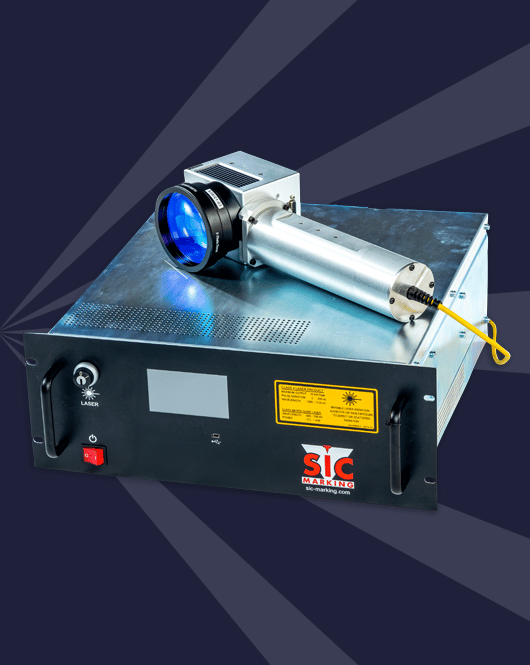

Laser wire stripping is a new and complex technology that SIC MARKING has mastered thanks to numerous applications for clients.

The wide range of lasers at SIC MARKING’s disposal allows it to choose the most suitable for each case, based on the client’s insulation material.