our solutions > workshop range > laser stations

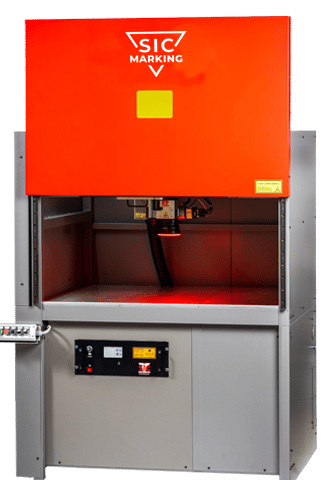

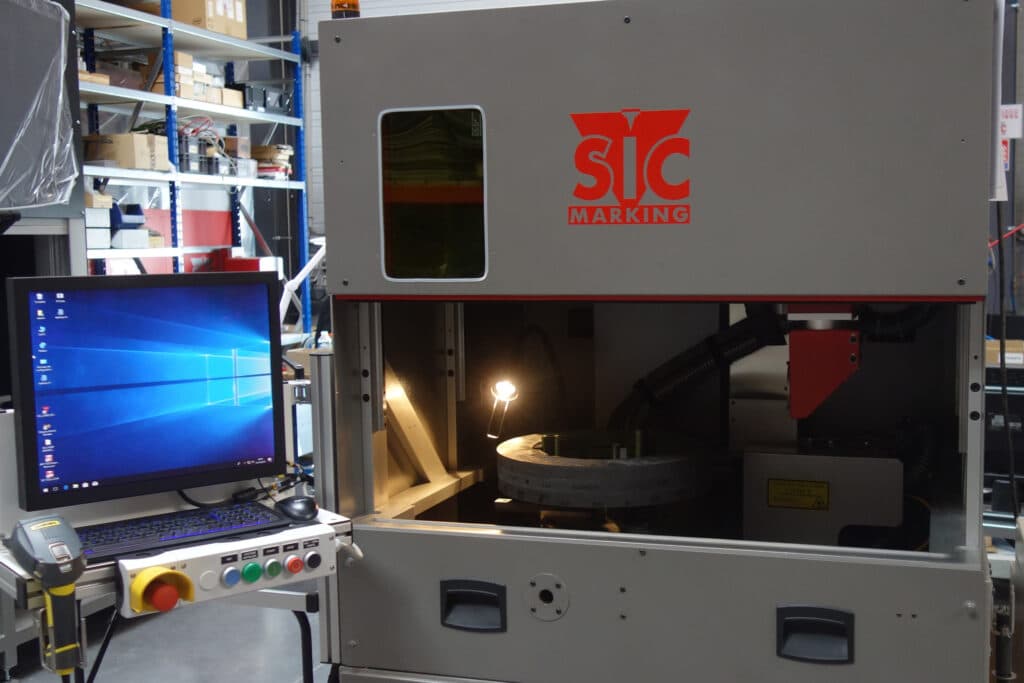

Laser Station XXL-BOX

The XXL-BOX is a safe Class 1 laser marking station with automatic door.

It is fully modular and can mark large parts.

This station is also suitable for surface preparation operations such as cleaning or roughening.

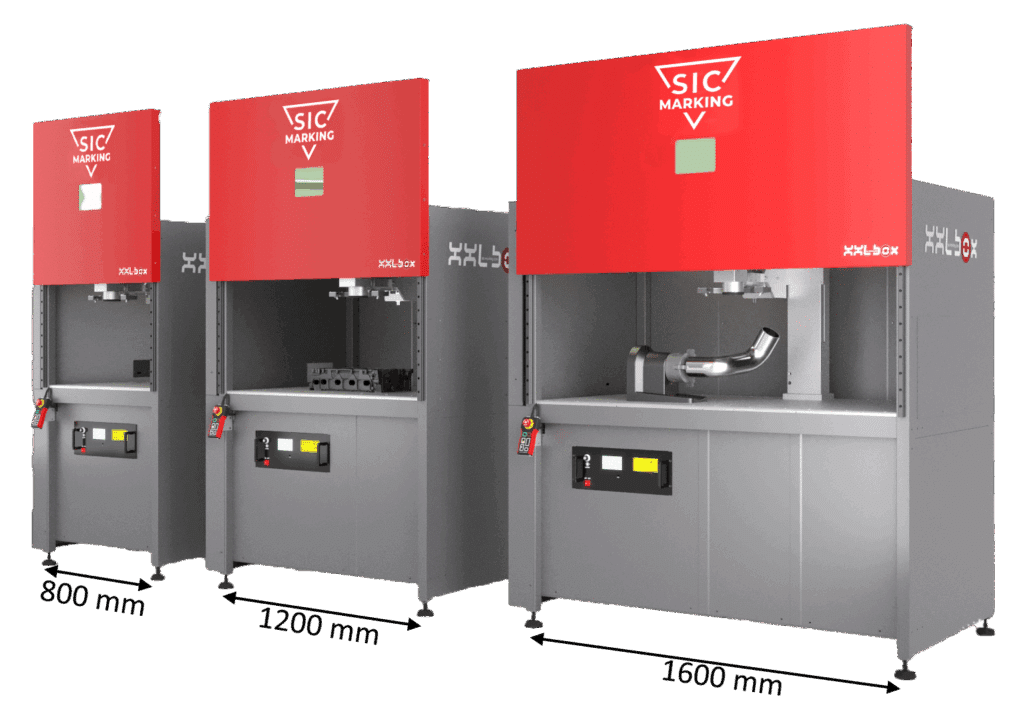

The XXL-BOX is available in 3 widths: 800, 1200 or 1600mm. It is equipped with a fiber laser ranging from 20W to 100W, to meet the most demanding applications.

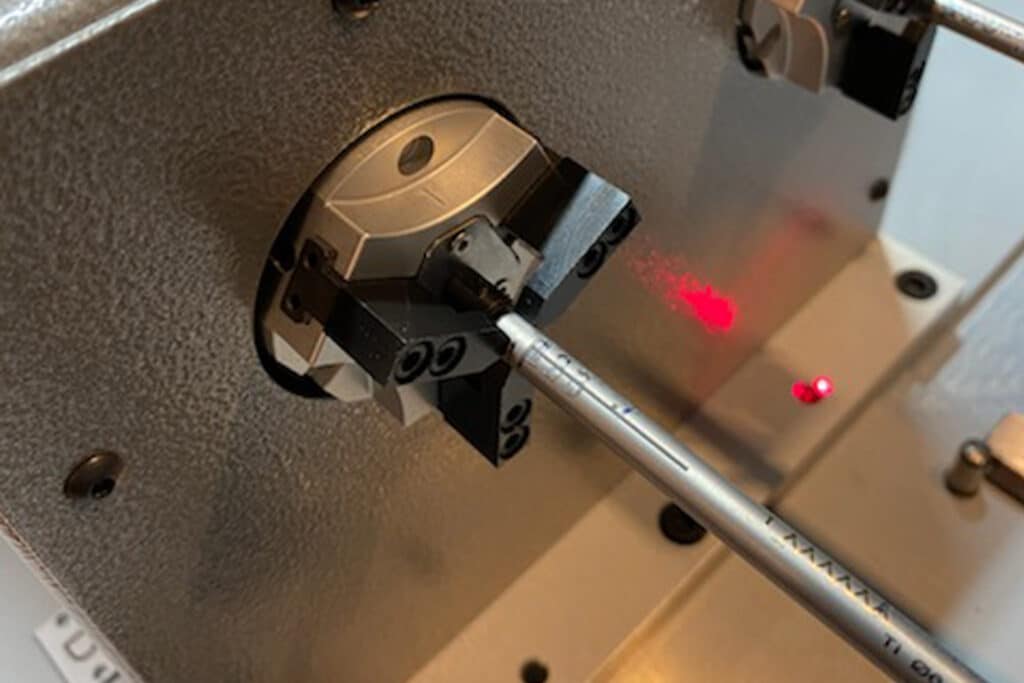

Its modular design enables the integration of various options (marking head integrated code reading, 3D module).

Different axis configurations enable the XXL-BOX to adapt to your production process.

The XXL-BOX is also a turnkey solution that can be easily integrated into a robotic cell.