×

SIC MARKING specialises in permanent marking and traceability, and provides its expertise for your projects, irrespective of the material being worked.

We are experts in steel, stainless steel, aluminium, plastic and copper, and can meet your more specific needs, such as engraving on carbon, titanium, ceramic, rubbers or on alloys such as Inconel, brass, bronze…

Is the material you want to mark specific?

SIC MARKING has a proven expertise in carbon, titanium, ceramic, rubber, and also on alloys such as Inconel, brass, bronze.

Find their characteristics here.

SIC MARKING’s teams of experts work alongside you to meet your industrial requirements and define with you the most suitable technical solution: laser marking technology, dot peen marking or scribing, standard or custom machine.

Each project is tested in a test laboratory, to obtain a high-quality marking.

Carbon is both rigid and light, and is mainly used in aircraft and in high-end automobiles.

The most suitable technology for carbon is the laser.

For the best readability, SIC MARKING recommends the laser marking machine i104 High Power, in order to obtain high quality deep markings.

Titanium is light, resists corrosion, erosion and fire, and also has excellent mechanical properties.

This metal is particularly present in the aircraft industry, where parts are subjected to high stresses (thermal, mechanical). Dot peen marking machines are the most suitable for these applications .

Titanium is also found in the medical sector (implants).

In this case, laser technology is the most appropriate.

Many alloys are encountered in the marking sector.

Inconel, for example, consists of nickel, iron, chromium and titanium.

Its anti-corrosion properties and heat resistance make it very useful in the shipbuilding and aerospace industries, and also in pollution control equipment.

The best marking results are obtained by dot peen marking (aircraft jet engine blade).

Brass is a mixture of copper and zinc.

This alloy is an excellent thermal and electrical conductor, and is mainly used in general mechanical engineering, pipe systems and valves/taps.

Bronze is a copper-tin alloy and is also used in taps.

These two alloys achieve excellent results with laser technology or dot peen marking.

This clay is shaped and then baked at temperatures varying up to 1000°C.

The ceramic thus obtained has excellent mechanical strength and hardness, and also resists wear and high temperatures.

It is also an excellent electrical and thermal insulator.

It is used in the construction (tiles, sanitary), steel, automotive (particle filters and spark plugs), aviation, electronics (capacitors) sectors, or in the glass industry and medical industry (ball joints).

Dot peen marking and laser technologies can achieve excellent marking on ceramic.

Rubber can be obtained either by the transformation of latex (resin extracted from certain plants such as rubber) or synthetically from fossil hydrocarbon molecules.

Rubber is widely used in industry for its anti-corrosion and anti-abrasion properties, and it also resists chemicals and acids.

It is particularly used in the automotive industry for the manufacture of tyres, gaskets and belts, and is also used toy manufacturing and in many other sectors.

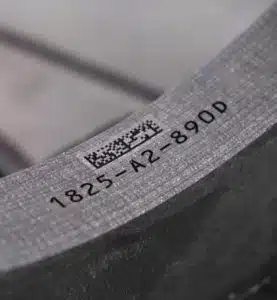

Laser marking technology produces high quality markings (datamatrix), and also changes the surface (matting).

Take a look at our case studies

Discover other materials

In addition to the conditions and requirements for marking a part, its inherent characteristics will determine the choice of the most suitable marking technology (laser, dot peen marking or scribing)

and the right marking machine (power, speed, portability, etc.).

The material, as well as the finish of the surface to be engraved, play a decisive role in making the right choice.

Contact us

Need information?

Contact one of our experts!