×

In an industrial environment where reliability, speed, and repeatability are essential, laser marking stands out as a solution particularly well suited to operational constraints.

Laser marking can be used on a wide range of materials, such as metals, aluminum, or plastics, without any tool change. This offers great flexibility in workshops and simplifies the management of varied production runs.

Designed for demanding production environments, laser marking integrates easily into short cycles and high-speed series while maintaining consistent quality, even at high volumes.

Laser technology produces fine, clean, and uniform markings, perfectly suited to modern traceability requirements, with codes and information that remain easy to read and reread over time.

Operating without physical contact with the part, laser marking requires no clamping or mechanical force, reducing equipment wear and preserving the integrity of the marked parts.

With no vibration, no impact, and virtually silent operation, laser marking contributes to a more comfortable working environment for operators.

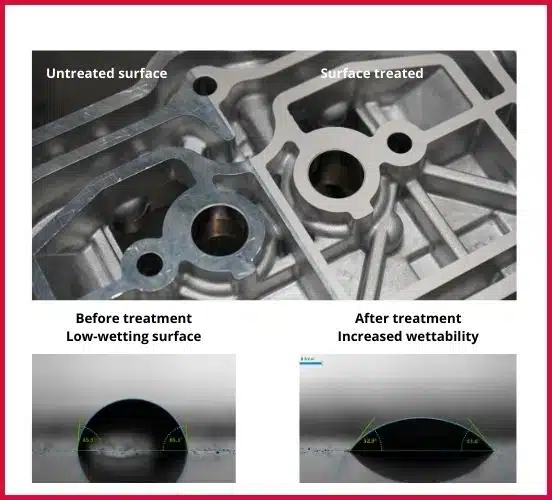

When combined with appropriate surface preparation, laser marking also helps optimize contrast and marking quality, ensuring reliable readability for both the human eye and vision systems.

Need information ?

Contact one of our experts !