×

Painting, shot blasting, heat treatment : all these processes can put your markings to the test.

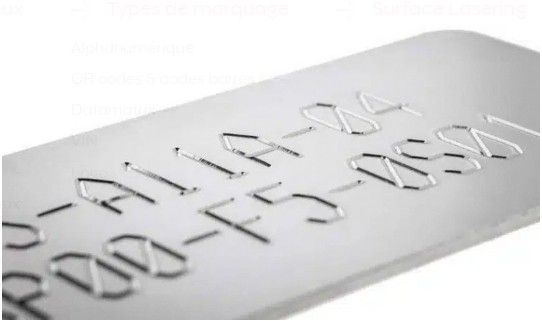

At SIC MARKING, we design solutions built to endure, ensuring your identifiers remain clear and traceable even after the toughest treatments.

Reaching depths of up to 0.2 mm, it guarantees maximum resistance to wear, heat, and chemical exposure.

The result: a marking that stays perfectly readable, from production to final inspection.

✔️ Fewer touch-ups and rework after finishing

✔️ Reliable DataMatrix and ID scans during production and maintenance

✔️ Compliance and traceability throughout the part’s entire lifecycle

✔️ Durable marking even on raw or complex surfaces

Every application is defined according to:

🔻 Material and surface condition (raw, treated, painted)

🔻 Target depth and cycle time

🔻 Production environment (open workshop, cell, robotized line)

🔻 Geometry and accessibility of the part

▪️ Pneumatic dot peen – for great depth and challenging environments

▪️ Scribing – continuous, highly legible lines

▪️ High-power fiber laser – precise, clean engraving for logos and DataMatrix codes

💬 Facing readability issues after finishing?

Our team is here to help you find the most efficient and durable solution

Need information ?

Contact one of our experts !